-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partner

- |

-

Valuta:Localizza i tuoi contenuti

Puoi impostare la valuta che preferisci per questo account.

Scegli una valuta

Valuta- SCEGLI LA TUA VALUTA

Aggiorna valuta

La modifica della valuta comporterà l'eliminazione del carrello corrente. Fare clic su OK per procedere.

Per mantenere il carrello attuale, fai clic su CHIUDI e poi salva il carrello prima di cambiare valuta.

-

Seleziona Conto

Il cambio di account aggiornerà il catalogo dei prodotti a tua disposizione. Quando cambi account, il tuo carrello attuale non verrà spostato nel nuovo account selezionato. Il tuo carrello attuale sarà disponibile se accedi nuovamente a questo account.

Account# Nome utente Città Codice postale CANCELLAREPROCEDEREIl mio conto

-

Software

- View All Produttività

- Comunicazione e messaggistica

- Business Intelligence

- Gestione delle attività e della forza lavoro

- Prelievo ed evasione ordini

- Consegna

- Logistica di ritorno

- Gestione dei dispositivi

- SwiftDecoder

- Etichettatura con codici a barre

- Strumenti di sviluppo

- Browser ed emulatori

- Sviluppo del software di scansione TotalFreedom

-

Assistenza

- View All Soluzioni di rilevamento

- Modulo di contatto vendite

- Technical Support

- Sedi globali

- Certificates

- Blog (US)

- Return Material Authorization (Test & Measurement)

- Return Material Authorization (Citytech)

- EnviteC - Return Material Authorization (RMA)

- Distributor Inventory

- eCOM Portal

- City Technology Materials Safety

- EnviteC Cross Reference List

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partner

- |

Stai sfogliando il catalogo prodotti per

Stai visualizzando la panoramica e le risorse per

- Servizi

- Automazione

- Engineering Services

ENGINEERING SERVICES

Custom Warehouse System Layout and Design That Meets Your Operation's Needs

In a world where no two fulfillment operations are alike, standard solutions can’t always address the most challenging or unique business requirements. That’s why we offer Engineered Solutions: a team of material handling, software and control engineers dedicated to creating custom solutions for your biggest challenges.

Engineered Solutions allows you to put the industry’s most experienced and knowledgeable experts to work on your specific fulfillment problem, scenario or upgrade — before you make a big investment in equipment or technology.

Whether you’re trying to meet peak season demand levels, adapt to new product profiles, achieve new levels of overall equipment effectiveness, or meet changing customer requirements, Engineered Solutions provides a wide range of professional services to help you streamline the change management process. This multidisciplinary approach offers you an efficient resource for assessing your business requirements and developing custom, cost-effective solutions to increase the effectiveness of your fulfillment operations.

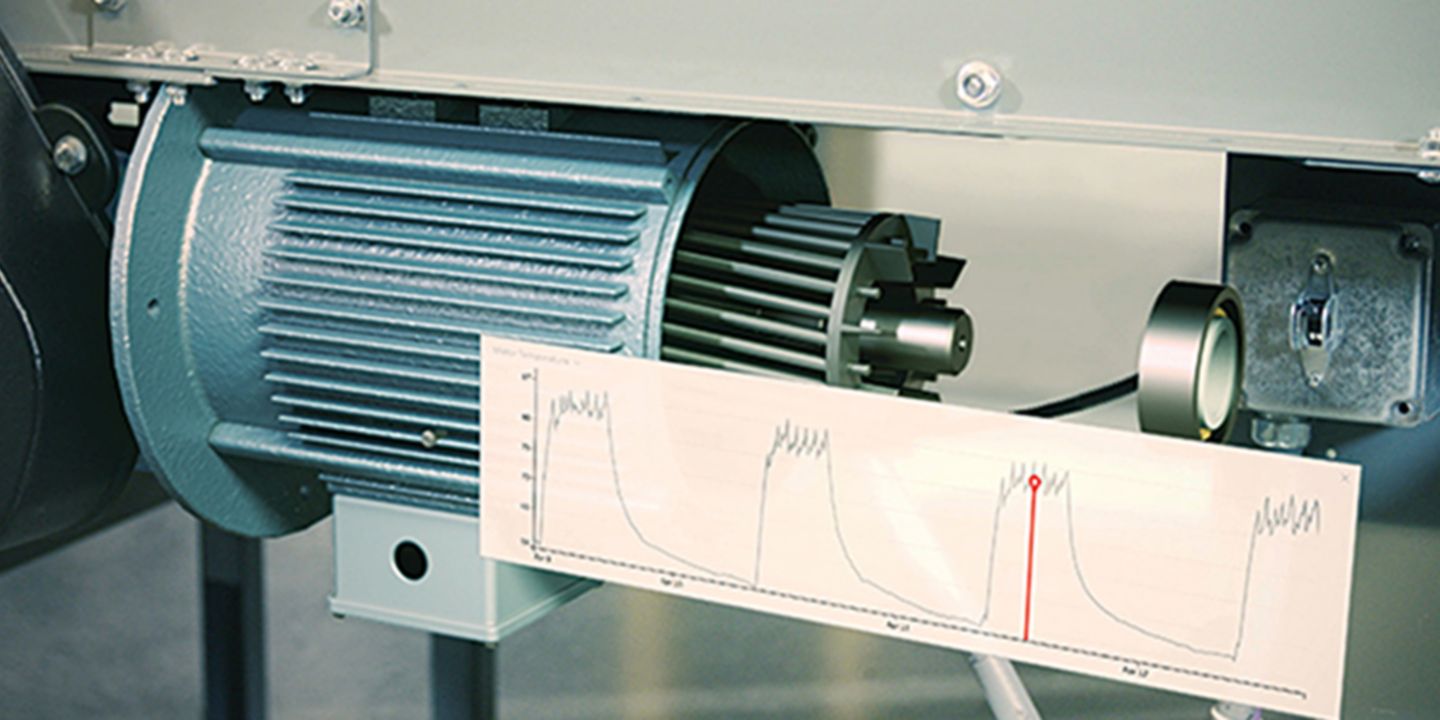

Maintain Best Practices While Minimizing Downtime

Maintaining the uptime of material handling equipment (MHE) is critical to your operational success, especially when you consider that most downtime is preventable. Audits and assessments can maximize the efficiency of your operation, while identifying asset, maintenance and functional opportunities.

The Honeywell Intelligrated Lifecycle Support Services (LSS) team provides levels of experience and expertise unmatched by any third-party provider. They have a deeper understanding of your system’s design, maintenance and requirements that only an original equipment manufacturer (OEM) can provide, plus robust data to back their claims and recommendations. In addition, all LSS auditors and assessors are subject matter experts (SMEs) who either maintain, have maintained, or have led a technical team in support of real-world operations like yours.

Audits

LSS audits provide you with expert consultation designed to identify process gaps and improve your operation. Whether you’re trying to identify unknown factors that are causing unscheduled downtime, struggling to meet maintenance schedules or key performance indicators (KPIs), or looking for strategies to improve performance, each audit is custom-tailored to meet your specific objectives.

Depending on your operation’s unique needs, LSS audits offer a variety of options. This variable scope can include any combination of the following:

- Uptime, parcel count, preventive maintenance scheduling, parts usage, and other KPIs

- Internal information systems (IRIS, iCampus, Dashboard)

- Technician proficiency and compliance to processes

- Maintenance shop layout and 5S standards

- Timekeeping and general administrative tasks

- Root cause analysis (RCA) and lessons learned tracking

- New technology implementation

Preventive Maintenance Audits

Preventive maintenance audits evaluate your maintenance standards, practices and systems to ensure that those systems are getting the maintenance they need to function at optimum capacity.

Technician Proficiency Audits

Technician proficiency audits assess the aptitude of your technicians to learn how efficiently they’re performing, identify potential expertise gaps, and recommend opportunities for skill improvement.

Field Maintenance Audits

Field maintenance audits provide a general overview of your equipment and maintenance practices.

Assessments

LSS assessments can help your organization to prevent issues and preserve system uptime by proactively evaluating overall system performance and health risks. An expert assessment team deploys a proven, field-tested approach to gauge operational performance and conditions against established benchmarks.

Every assessment includes the following services and deliverables:

- Expert evaluation of major components and an overview report prior to leaving site

- Follow-up, detailed report with a summary of findings, risk level for each major component, and recommendations for improvement

- Inspection certificate containing photos and measurement data (when applicable)

- Recommendations for upgrades or product enhancements

- Parts quote for replacement components

- Discussions to ensure clear understanding of findings and recommendations

Reliability Assessments

Reliability assessments evaluate your equipment’s operational condition and functionality levels. You’ll get a detailed inspection of critical components, plus root cause analysis (RCA) and prioritization of maintenance actions or part replacements. The LSS team will also recommend engineered solutions, if needed, to bring equipment back to designed operating standards or reduce the risk of unplanned downtime.

Optimization Assessments

Optimization assessments review the effectiveness of maintenance programs and seek to optimize operator interactions with MHE. You’ll get recommendations for best-in-class asset management, with a focus on increasing throughput.

Audit or Assessment: Which Is Right for You?

Although LSS audits and assessments provide resources to identify opportunities, mitigate risks, and help your facility to run more effectively, each offering focuses on different aspects of your operation.

Audit

- Consultation to identify process gaps

- Reviews performance of people or processes

- Eliminates “tribal” knowledge loss by documenting procedures to inform training

- Provides actionable insights about your systems and maintenance procedures

Assessment

- Thorough inspection of equipment, including mechanical and electrical components

- Design review against original drawings and bills of material (BOMs)

- Expert recommendations to improve or enhance your equipment’s functionality

Changes to Business Operations

As you confront the challenges of modernizing legacy control systems, Engineered Solutions provides obsolescence planning for critical control system components. These projects help you reconcile obsolescence while providing modern enhancements to deliver increased system capacity, flexibility and longevity. Modifications and upgrades include the following services:

Controls and Software

- Complete control platform upgrade or replacement

- Mid-life system technology refreshes

- PLC and HMI replacement

- Obsolescence- or performance-driven variable frequency and servo drive replacements

- Obsolescence- or performance-driven scanner and vision upgrades

Mechanical and Electrical

- Line, tilt-tray and cross-belt sorter rebuilds and upgrades for maximum efficiency, uptime and accuracy

- ZoneFlex® Advanced increases throughput up to 45%, improves product handling, and reduces side-by-sides on existing conveyor lines

- Palletizer upgrades, retrofits and repurposing to enhance operation, productivity, safety and support product and packaging changes

- Product enhancement updates (PEUs) for scalable, continuous improvement

Related Content

Engineering Services

Mettiamoci in contatto!

Iscrivetevi per ricevere comunicazioni esclusive da parte di Honeywell su aggiornamenti di prodotti, informazioni tecniche, nuove offerte, eventi e notizie, sondaggi, offerte speciali e argomenti correlati tramite telefono, e-mail e altre forme di comunicazione elettronica.

Copyright © 2025 Honeywell International Inc

Dimensioni massime file

Numero massimo di file superato

A causa dell'inattività verrai disconnesso 000 secondi.

Dimensioni massime file

Numero massimo di file superato

Non puoi accedere a questa pagina poiché questo prodotto non è disponibile nel tuo Paese.