-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

-

Currency:Localize your Content

You can set your preferred currency for this account.

Choose a Currency

Currency- CHOOSE YOUR CURRENCY

Update Currency

Changing Currency will cause your current cart to be deleted. Click OK to proceed.

To Keep your current cart, click CLOSE and then save your cart before changing currency.

-

Select Account

Switching accounts will update the product catalog available to you. When switching accounts, your current cart will not move to the new account you select. Your current cart will be available if you log back into this account again.

Account# Account Name City Zip/Post Code CANCELPROCEEDMy Account

-

Support

- View All Productivity Solutions

- Warranties

- Patents

- Global Locations

- Technical Support

- Discontinued Products

- Quality Program and Environmental Compliance

- Return Material Authorization (RMA)

- Legal Documents

- Product Certification

- Software Downloads

- Cyber Security Notifications

- Case Studies and Success Stories

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

You are browsing the product catalog for

You are viewing the overview and resources for

- News & Events

- Featured stories

- Uncover Hidden Efficiencies in Your DC

Uncover Hidden Efficiencies in Your DC

Uncover Hidden Efficiencies in Your DC

Garrett Rysko, Mitul Desai

June 3, 2022

Even though you need to ship more products faster than ever before, you’re probably grappling with a perfect storm of unpredictable disruptions. The most common challenges we hear about are labor, throughput and technology. Any one of these can squeeze profits and reduce productivity; together, their collective impact can quickly add up.

These common problems are frequently compounded by “silos” of data and isolated systems. As a result, many managers lack visibility into asset performance and bottlenecks, underestimate unplanned downtime, and aren’t agile enough to optimize their labor force.

With growing e-commerce demand and increasingly tight service level agreements (SLAs), even small increases in productivity and cost savings can significantly impact your bottom line. And the key to unlocking these hidden opportunities for efficiency can likely be found in the data you’re already generating every day.

Your DC May Be Trying to Tell You Something

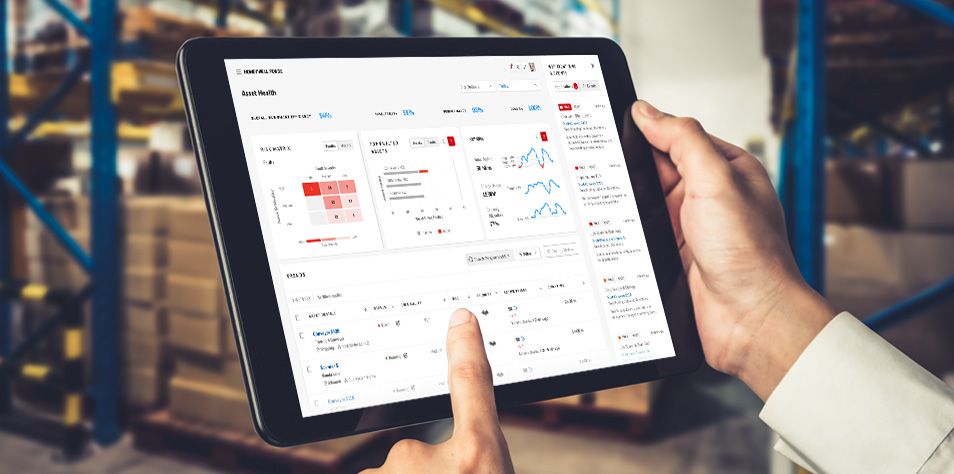

Something amazing happens when DC managers have access to consolidated performance metrics, actionable alerting and smart decision-making recommendations. These advantages enable constant collaboration across operations and maintenance teams. As a result, your operation can better anticipate and even prevent unplanned downtime, while improving the utilization of your systems in real time throughout the day.

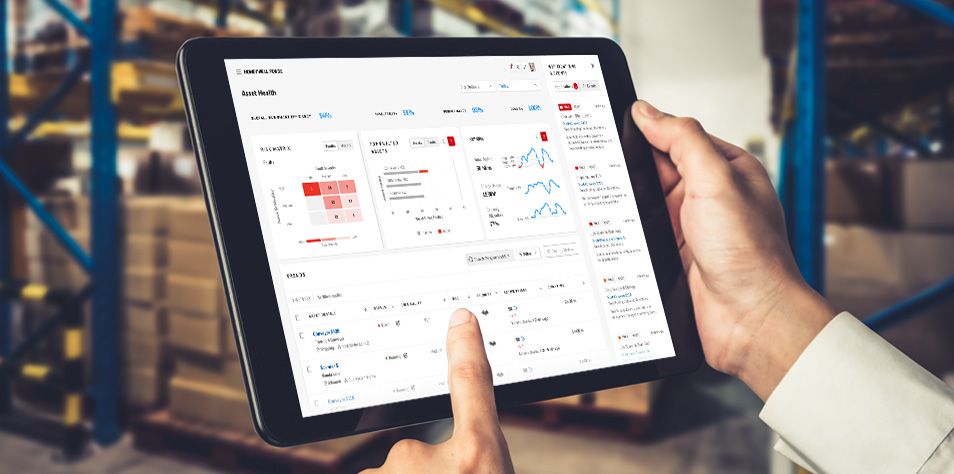

To make these advantages easily accessible to growing distribution operations, we recently introduced Honeywell Forge Connected Warehouse, an advanced enterprise performance management (EPM) software solution that combines data from islands of automation and separate software tools. This asset-based operational system of record provides operations and maintenance teams with a digital assistant to optimize DC labor, maintenance and operations. The platform is designed to help DCs unlock hidden potential, prevent unplanned downtime, and graduate from manual cost centers to digital distributors.

Without the need for an expensive rip-and-replace project or business downtime, implementation is easy. Honeywell Forge Connected Warehouse is designed to integrate multiple different systems (even if not from Honeywell) to your existing systems and assets while creating new capabilities. As a result, you can start right away with the equipment you have, identify key areas for focus, and leverage your existing assets to create new capabilities — enabling increased economic outcomes.

Join Us for an Informative Webinar That Could Improve Your Cost per Case Shipped

On June 23 at 2 p.m. EDT (11 a.m. PDT), we’ll present a free 30-minute On The Move webinar exploring how Honeywell Forge Connected Warehouse can help you uncover hidden warehouse and supply chain efficiencies to achieve a better cost per case shipped.

Register today to learn how Honeywell Forge Connected Warehouse enables maintenance teams to get ahead of common challenges and increases the utilization of assets in critical paths while providing the visibility operations managers need to focus on performance, elevate insights, and manage their teams more efficiently.

To subscribe to the Honeywell Intelligrated blog and get exclusive communications and updates, click here.

Let's Connect!

Sign up to receive exclusive communications from Honeywell including product updates, technical information, new offerings, events and news, surveys, special offers, and related topics via telephone, email, and other forms of electronic communication.

Copyright © 2025 Honeywell International Inc

Maximum File Size

Maximum Files Exceeded

Due to inactivity you will be logged out in 000 seconds.

Maximum File Size

Maximum Files Exceeded

You cannot access this page as this product is not available in your country.