Some of us might not remember a world before the humble barcode existed. In the 50 years since a pack of chewing gum in an Ohio grocery store became the first product to be scanned with a barcode, this technology has transformed industry, from retail shelves, to the hospital bedside, to the airport check-in counter, to name just a few.

Barcode Types and Capabilities

To the untrained eye, barcodes might all look similar, but there are different types and formats of barcodes used for different purposes, with new advances in capability all the time. Universal product codes (UPCs), for example, have 12 digits under the barcode and are used to identify retail products. Code 39, a 1-D code used in the healthcare, automotive, electronics and defense sectors, can encode 39 to 43 characters. Intermec Corporation (now Honeywell) developed the Code 39 symbology back in the 1970s.1 GS1-128 is yet another type of barcode that can create long codes in a compact space for logistics and transportation.2

Another method of barcoding is Direct Part Marking (DPM), a process that permanently imprints parts with product information such as serial numbers, part numbers, date codes and barcodes. This permanent marking facilitates the tracking of parts throughout their entire life cycle. The definition of 'permanent' can vary based on the specific context in which the part is utilized.

The Quick Response (QR) code, a square-shaped 2-D barcode, represents a way the traditional barcode has evolved. QR codes were standardized by the International Organization for Standardization (ISO) in 2014, which boosted their adoption. As QR codes can be scanned by a smartphone, they are often used for payment, authentication, marketing, social media purposes and for providing operators and customers with relevant product, service and warranty information.

The barcode also serves as a gateway for integrating new technologies throughout the supply chain, including machine vision, robotics and drones; the multiple barcode applications, along with RFID technology and machine vision, will be the foundation moving forward for supply chain operations.

Industries Transformed by the Barcode

Healthcare - In 2004, the U.S. Food and Drug Administration (FDA) started requiring certain medications be labeled with a barcode. By capturing a medicine’s name, specific dose and manufacturer through the barcode, clinicians could enhance patient safety and avoid giving counterfeit, expired or incorrect drug dosages to patients.3 Since then, studies have shown significant reductions in adverse drug events and lower rates of errors in medication administration timing when barcodes are used.4 Today, you can find barcodes not just on medicines but on patient wristbands for identification and linking to their electronic medical record as well as on various surgical instruments for tracking purposes.

Air Travel - Automated baggage tags started appearing on luggage in the early 1990s. These tags include a barcode to help make sure the right bags make it on the right airplanes and to the right final destinations. Before then, luggage tags were hand-written or color-coded to help determine where the bag was eventually going.5 Barcodes have helped to error-proof the process of checking and retrieving bags: in 2023, less than 6 of every 1,000 passenger bags were mishandled by airlines.6

Agriculture - Pressure has ramped up recently for transparency throughout the food supply chain. Consumers and regulators want to understand where different ingredients come from and be able to trace them back to the source in the case of any contamination event or recall.7 Barcodes are one technology enabling this traceability throughout food production, processing, and distribution.

Over the years, barcodes have also helped further agriculture research. In 1988, Honeywell8 used its automatic identification and data capture (AIDC) expertise to help the U.S. Department of Agriculture better understand honeybee pollination. The company created the world’s smallest barcode labels attached to individual bees to track their movement and study their behavior.

The Barcode’s 50th Anniversary

These three examples are just scratching the surface of changes and advancements the barcode has helped bring about over the last 50 years in sectors from retail to manufacturing to logistics. Barcodes continue to provide businesses today with important data on product buying trends, shipment status, quality control and more.

Honeywell’s decades of innovation and technology acumen have helped to advance the barcode from its initial concept to what it is today. For example, Honeywell9 was part of the development and integration of RFID technology into barcode printing systems for enhanced tracking and inventory management. It also introduced the first omni-directional handheld laser scanner, allowing barcodes to be scanned from any angle, and the first solution to incorporate both barcode scanning and voice in one device, integrating hands-free voice and barcode scanning capabilities for warehouse and distribution center workflows.10

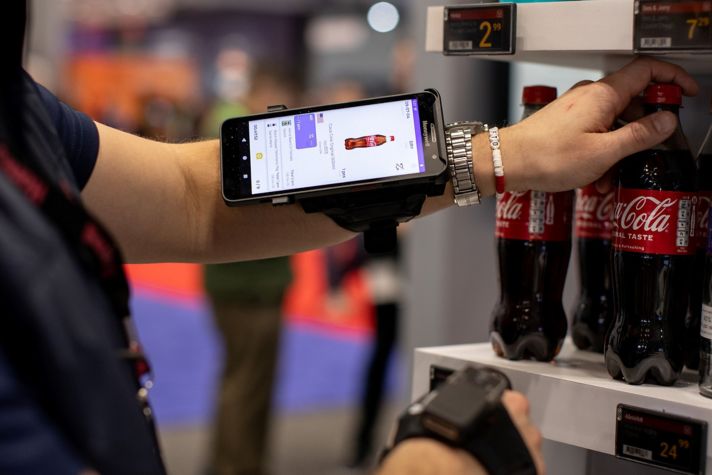

Fast forward to today, and Honeywell offers a comprehensive range of the latest barcoding and machine imaging solutions in the AIDC space to bring greater efficiency and accuracy to today’s companies. Our barcode-decoding software can be found in drones scanning warehouse inventory and in kiosks at big box stores’ self-checkout. Our barcode scanners are in hospitals helping nurses work more efficiently, in warehouses speeding up worker throughput, and in retail stores helping associates serve customers efficiently. Our scanner-equipped mobile computers are under the wing of airplanes enabling workers to track baggage for customers as they travel internationally.

“Honeywell remains at the forefront of developing technologies that help to automate, digitize and bring greater data-driven insights to our customers,” said Paul Crimm, Chief Technology Officer of Honeywell Productivity Solutions and Services. “Technologies like machine vision are already building on the functionality of the barcode and exceeding the capabilities of yesterday’s barcode tech. Honeywell is perfectly positioned to pioneer the application of these automated ID and data collection technologies with new solutions.”

To learn more about Honeywell’s contributions to the barcode’s evolution over time and explore what the future holds for barcodes, visit our dedicated site where we are celebrating the 50th anniversary of the barcode.

Sources:

1 - Honeywell acquired Intermec in 2013.

2 - https://getcircuit.com/teams/blog/guide-to-barcode-types

3 - https://medicalcourier.com/barcode-history-healthcare-specimen-tracking

4 - www.nejm.org/doi/full/10.1056/NEJMsa0907115

5 - www.slate.com/articles

6 - www.bts.gov/content/mishandled-baggage-reports-filed-passengers-largest-us-air-carriersa

7 - www.agritechtomorrow.com/news/2023/10/26/barcode-labeling-and-rfid-tracking-solutions-for-agriculture/15010

8 - Honeywell acquired Intermec in 2013.

9 - Honeywell acquired Intermec in 2013.

10 - 50th Anniversary of the Barcode | Honeywell