-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

-

Currency: USDLocalize your Content

You can set your preferred currency for this account.

Choose a Currency

Currency- CHOOSE YOUR CURRENCY

Update Currency

Changing Currency will cause your current cart to be deleted. Click OK to proceed.

To Keep your current cart, click CLOSE and then save your cart before changing currency.

-

Select Account

Switching accounts will update the product catalog available to you. When switching accounts, your current cart will not move to the new account you select. Your current cart will be available if you log back into this account again.

Account# Account Name City Zip/Post Code CANCELPROCEEDMy Account

-

Support

- View All Productivity Solutions

- Warranties

- Patents

- Global Locations

- Technical Support

- Discontinued Products

- Quality Program and Environmental Compliance

- Return Material Authorization (RMA)

- Legal Documents

- Product Certification

- Software Downloads

- Cyber Security Notifications

- Case Studies and Success Stories

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

You are browsing the product catalog for

You are viewing the overview and resources for

Unlock Operational Excellence

In the fast-paced Transportation, Logistics, and Warehouse industry, agility is key to meeting evolving customer demands. That's why Honeywell Productivity Solutions offers the hardware and software solutions your operations need the most.

Unlock Superior Performance

In demanding industrial and transportation environments, precision and durability are required. Honeywell MICRO SWITCH NGC Series Miniature Limit Switches offer a cutting-edge solution for applications where space is tight, conditions are extreme, and reliability is critical.

Precision Scanning Built to Last

Experience unmatched performance and rugged durability designed for ultimate productivity with the Honeywell Granit™ Ultra barcode scanner. Engineered to provide exceptional scan capabilities, outstanding durability, and effortless usability - perfect for even the toughest scanning tasks.

Learn MoreUnlock Operational Excellence

In the fast-paced Transportation, Logistics, and Warehouse industry, agility is key to meeting evolving customer demands. That's why Honeywell Productivity Solutions offers the hardware and software solutions your operations need the most.

Unlock Superior Performance

In demanding industrial and transportation environments, precision and durability are required. Honeywell MICRO SWITCH NGC Series Miniature Limit Switches offer a cutting-edge solution for applications where space is tight, conditions are extreme, and reliability is critical.

Precision Scanning Built to Last

Experience unmatched performance and rugged durability designed for ultimate productivity with the Honeywell Granit™ Ultra barcode scanner. Engineered to provide exceptional scan capabilities, outstanding durability, and effortless usability - perfect for even the toughest scanning tasks.

Learn MoreUnlock Operational Excellence

In the fast-paced Transportation, Logistics, and Warehouse industry, agility is key to meeting evolving customer demands. That's why Honeywell Productivity Solutions offers the hardware and software solutions your operations need the most.

Contact an expert now

From digitalization to optimization with AI, Honeywell uses automation to meet you where you are now andhelp you go further.

Get started with myAutomation

We're making it easier for you to shop and search for products, manage your orders, and request digital support for your Integrated Journey.

Discover Our Latest Industrial Automation Solutions

Discover our comprehensive range of industrial automation solutions designed to optimize efficiency, enhance precision, and drive productivity.

CURRENT SENSORS

CSSV1500 Series

Current measurement for battery management systems in electrified vehicles.

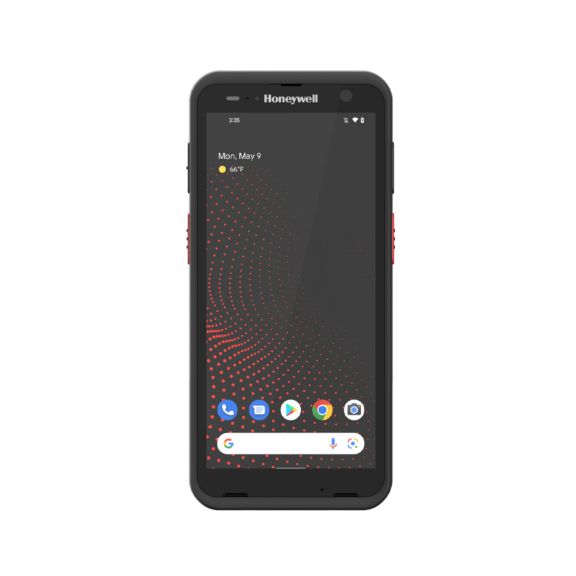

MOBILE COMPUTER

CT70

Ultra-rugged, ultra-reliable, 5G connected device for enterprise customers that need a future-ready device.

MULTI-GAS

OmniPoint

The OmniPoint™ transmitter is a comprehensive gas detection solution for hazardous locations.

REMOTE TERMINAL UNITS

ControlEdge™ RTU

A powerful, modular and scalable controller capable of all remote automation and control applications.

ELECTRICITY

A4CI

Delivering real-time data insights and edge intelligence for today’s metering needs.

SINGLE BURNERS

ThermAir

Ideal on heaters, textile ovens and in situations where the fuel is highly variable.

Leading the Way in Digitalization

Technology is evolving and changing at a faster pace. As a thought leader in the industry, let Honeywell Industrial Automation be your partner in your digitalization journey.

Integrated Health, Safety & Security

Secure your data and operations with cybersecurity solutions that will ensure your business continuity plans.

Digital Workforce & Supply Chain

Embrace digital technology to redefine your supply chain from manual labor to dynamic, cutting-edge solutions.

Explore Our Offerings By Industry

Honeywell Industrial Automation has a complete portfolio of products, software, solutions, and services to support your needs. As experts in automation and digitalization, we want to partner with you to help you achieve your business goals.

Aerospace

We create safer, healthier, more comfortable and sustainable air travel with one of the industry’s broadest and most innovative offering portfolios.

Commercial Buildings

Safety from the ground up. Equipment failure is never an option especially on high-risk work sites.

Energy

We have the engineering expertise, sustainability commitment and solutions to help you drive a more sustainable future.

Government and Public Sector

We have been helping government and public sector entities for over 30 years, from military deployment operations to on-going support for public services.

Healthcare

We have the technologies to help both healthcare providers and medical equipment manufacturers shape the future of their organizations.

Life Sciences

We support life sciences with tools for biotechnology and medical devices, enhancing product quality, safety, and compliance in healthcare.

Manufacturing

Our focus is on ensuring a safe working environment, achieving stable production levels, adhering to quality standards, and reducing energy consumption.

Logistics and Warehouses

From mobility devices to facility management software and warehouse execution systems, we’re ready to help you create a safer, more productive workplace.

Retail

From the storefront to the distribution center and across the supply chain, our retail solutions bring together people, assets, and merchandise in powerful new ways.

Utilities

We have a diverse set of solutions that address the needs of utilities across each area of the utility value chain.

Aerospace

We create safer, healthier, more comfortable and sustainable air travel with one of the industry’s broadest and most innovative offering portfolios.

Commercial Buildings

Safety from the ground up. Equipment failure is never an option especially on high-risk work sites.

Energy

We have the engineering expertise, sustainability commitment and solutions to help you drive a more sustainable future.

Government and Public Sector

We have been helping government and public sector entities for over 30 years, from military deployment operations to on-going support for public services.

Healthcare

We have the technologies to help both healthcare providers and medical equipment manufacturers shape the future of their organizations.

Life Sciences

We support life sciences with tools for biotechnology and medical devices, enhancing product quality, safety, and compliance in healthcare.

Manufacturing

Our focus is on ensuring a safe working environment, achieving stable production levels, adhering to quality standards, and reducing energy consumption.

Logistics and Warehouses

From mobility devices to facility management software and warehouse execution systems, we’re ready to help you create a safer, more productive workplace.

Retail

From the storefront to the distribution center and across the supply chain, our retail solutions bring together people, assets, and merchandise in powerful new ways.

Utilities

We have a diverse set of solutions that address the needs of utilities across each area of the utility value chain.

What's New

Discover the latest stories and thought leadership from Honeywell Industrial Automation, showcasing innovations in manufacturing, healthcare, aerospace, logistics and warehouses, and more.

Ready to accelerate your automation journey?

Streamline your operations with proven industry support.

Let's Connect!

Sign up to receive exclusive communications from Honeywell including product updates, technical information, new offerings, events and news, surveys, special offers, and related topics via telephone, email, and other forms of electronic communication.

Copyright © 2025 Honeywell International Inc

Maximum File Size

Maximum Files Exceeded

Due to inactivity you will be logged out in 000 seconds.

Maximum File Size

Maximum Files Exceeded

You cannot access this page as this product is not available in your country.