-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

-

Currency:Localize your Content

You can set your preferred currency for this account.

Choose a Currency

Currency- CHOOSE YOUR CURRENCY

Update Currency

Changing Currency will cause your current cart to be deleted. Click OK to proceed.

To Keep your current cart, click CLOSE and then save your cart before changing currency.

-

Select Account

Switching accounts will update the product catalog available to you. When switching accounts, your current cart will not move to the new account you select. Your current cart will be available if you log back into this account again.

Account# Account Name City Zip/Post Code CANCELPROCEEDMy Account

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

You are browsing the product catalog for

You are viewing the overview and resources for

- News & Events

- Featured stories

- Personal Protective Equipment

- The Future of Ergonomic Safety Starts with the Right Harness

The Future of Ergonomic Safety Starts with the Right Harness

The Future of Ergonomic Safety Starts with the Right Harness

Alexandra Serban

22 October 2020

Fall protection equipment is straightforward – you fall off a ladder and your fall protection system prevents your free fall. Safety is attained. But can fall protection equipment help improve long-term worker health and well-being? The newest generation of harnesses promote ergonomic safety through innovation in comfort, usability, style and performance.

Beyond the risk of falling

Falls are serious safety risks, but did you know 31.4% of non-fatal injuries in construction are due to overexertion?

Over time, overexertion or highly strenuous physical activity leas to development of musculoskeletal diseases (MSDs).

MSDs are caused by “sudden or sustained exposure to force, vibration, repetitive motion, and awkward posture”, according to the CDC. They can develop over time, be episodic or chronic, and can evolve from mild to severe disorders.

In the workplace, they are caused by fixed or constrained body positions, fast-paced work, carrying heavy loads, and repetitive movements.

In the UK, 498,000 workers have suffered from work-related musculoskeletal disorders (new or longstanding) in 2018-2019, according to a Labour Force Survey (LFS). And 6.9 million working days were lost due to work-related musculoskeletal disorders in the same period, according to the same source.

Sprains, strains and tears represent 67% of nonfatal injuries and illnesses involving days away from work, according to the US Bureau of Labor Statistics.

For companies, absenteeism translates to lost productivity, and increased healthcare, disability, and compensation costs. Musculoskeletal disorders cost employers $50B annually, according to the US Bureau of Labor Statistics.

To help tackle this problem, NIOSH developed the Musculoskeletal Health Cross-Sector Program, an initiative focused on researching and preventing MSDs, by helping management mitigate related risks and liabilities, and helping practitioners improve the efficacy of workplace interventions.

PPE plays a key role in promoting musculoskeletal health in the workplace.

Designing an ergonomic harness

Construction is one of the highest averaging industries for musculoskeletal disorders (MSDs). Overhead work, lifting and lowering heavy objects put pressure on the back and shoulders. When performed repeatedly, these movements can lead to overexertion and pain.

When working at heights, in steel erection or scaffolding, workers perform these tasks spending long hours in restrictive, heavy harnesses. Impaired physical capability, along with sweat and heat build-up are oftentimes responsible for fall accidents and poor performance.

That’s why workers need safe, ergonomically comfortable harnesses.

A comfortable harness is anatomically designed to distribute the load, putting the right amount of pressure in the legs and waist, as opposed to the shoulders.

But ergonomic assessments are not mandatory. To obtain certification, harnesses typically pass a series of standard safety tests such as dynamic performance, static strength, and corrosion resistance.

“Most harnesses pass the safety test, but not an ergonomic test, if it were required,” says Marc Dudelzak, Offering Management Lead for Fall Protection at Honeywell. “Thinking about the future of ergonomic safety, we have redesigned our Miller H500 harness series to provide not only basic safety, but greater freedom of movement, a hassle-free donning experience, more breathability and better fit”.

Honeywell designed the H500 Series with this wheel of ergonomic safety in mind:

- Safety

- Intuitive use

- Breathability

- Freedom of movement

Workers remain dry and cool with a new anatomically and ergonomically-designed pressure-relief shoulder/back padding.

The new padding is 3x more breathable than other options on the market, according to water vapor resistance testing performed by Satra Technology.

“The padding is composed of layers, perforated foam in the middle and mesh at the exterior, to increase the level of breathability”, says Gazo Jozef, Engineering Manager for Honeywell. “The challenge was to create a breathable padding, which is also rigid and dense enough to load and protect the user when using an SRL.”

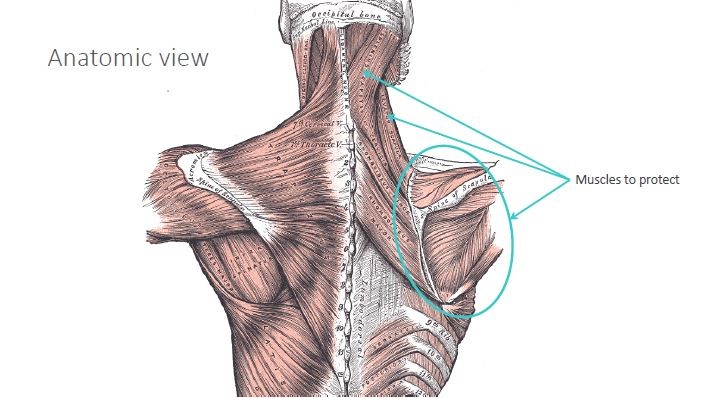

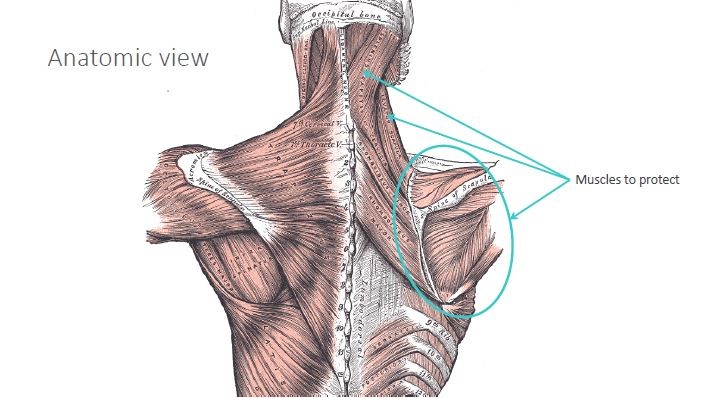

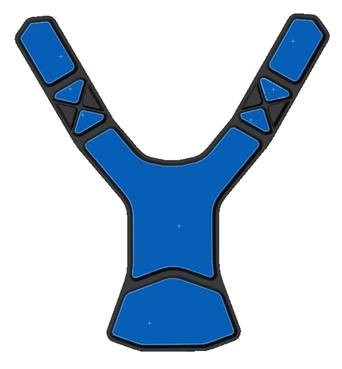

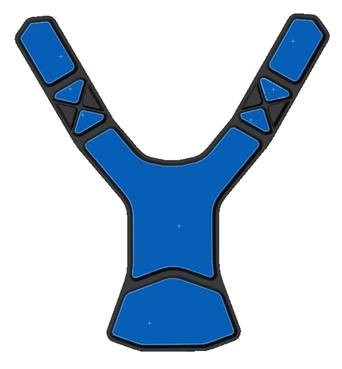

The new padding also minimizes overhead muscular fatigue. The “U” shape replaces the standard “X” shape to prevent fatigue in the upper neck area, by distributing the weight to the shoulders.

Description: Body Anatomy

Description: Body Anatomy

Description: Body Anatomy

Description: Body Anatomy

“During testing, we’ve realized the overhead work was uncomfortable because the padding wasn’t very flexible”, Jozef adds. “So, we’ve added an additional feature, a molded cross shape that allows the strap to deform when workers need to raise their hands.”

Description: The foldable padding feature

Description: The foldable padding feature

Description: The foldable padding feature

Description: The foldable padding feature

Safe, healthy and supported

Other smart and intuitive features include:

- A newly formulated water-repellent flex webbing flexes to accommodate movement and body contours for optimum comfort around legs and shoulders.

- Smart anti-tangle for easy donning

- Ergonomic waist pad for optimum lumbar support

- Clearly identifiable fall impact indicators and improved visible stick pattern for easy, hassle-free inspection

- Dedicated SRL web link to easy attachment of SRLs

Learn more about H500 features and benefits.

“Ultimately, a comfortable harness means you are more productive at work and less tired at the end of the shift, so you can go home safely and spend quality time with your family,” Jan Hrouzek, Design Engineer for Honeywell, concludes.

Let's Connect!

Sign up to receive exclusive communications from Honeywell including product updates, technical information, new offerings, events and news, surveys, special offers, and related topics via telephone, email, and other forms of electronic communication.

Copyright © 2026 Honeywell International Inc

Maximum File Size

Maximum Files Exceeded

Due to inactivity you will be logged out in 000 seconds.

Maximum File Size

Maximum Files Exceeded

You cannot access this page as this product is not available in your country.