-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- 파트너

- |

-

통화:콘텐츠 현지화

이 계정에 대해 선호하는 통화를 설정할 수 있습니다.

통화를 선택하세요

통화- 통화를 선택하세요

통화 업데이트

통화를 변경하면 현재 장바구니가 삭제됩니다. 계속하려면 확인을 클릭하세요.

현재 장바구니를 유지하려면 통화를 변경하기 전에 닫기를 클릭한 다음 장바구니를 저장하세요.

-

계정 선택

계정을 전환하면 사용 가능한 제품 카탈로그가 업데이트됩니다. 계정을 전환하면 현재 장바구니가 선택한 새 계정으로 이동되지 않습니다. 이 계정에 다시 로그인하면 현재 장바구니를 사용할 수 있습니다.

계정# 계정 이름 도시 우편번호 취소진행하다내 계정

귀하는 다음에 대한 제품 카탈로그를 검색하고 있습니다.

다음에 대한 개요와 리소스를 보고 있습니다.

- 제품

- 자동화

- Solutions by Strategy

- The Connected Distribution Center

- Connected Assets

Connected Assets

Increase System Performance and Reliability With Asset Lifecycle Management

Limit Downtime and Maximize Profits

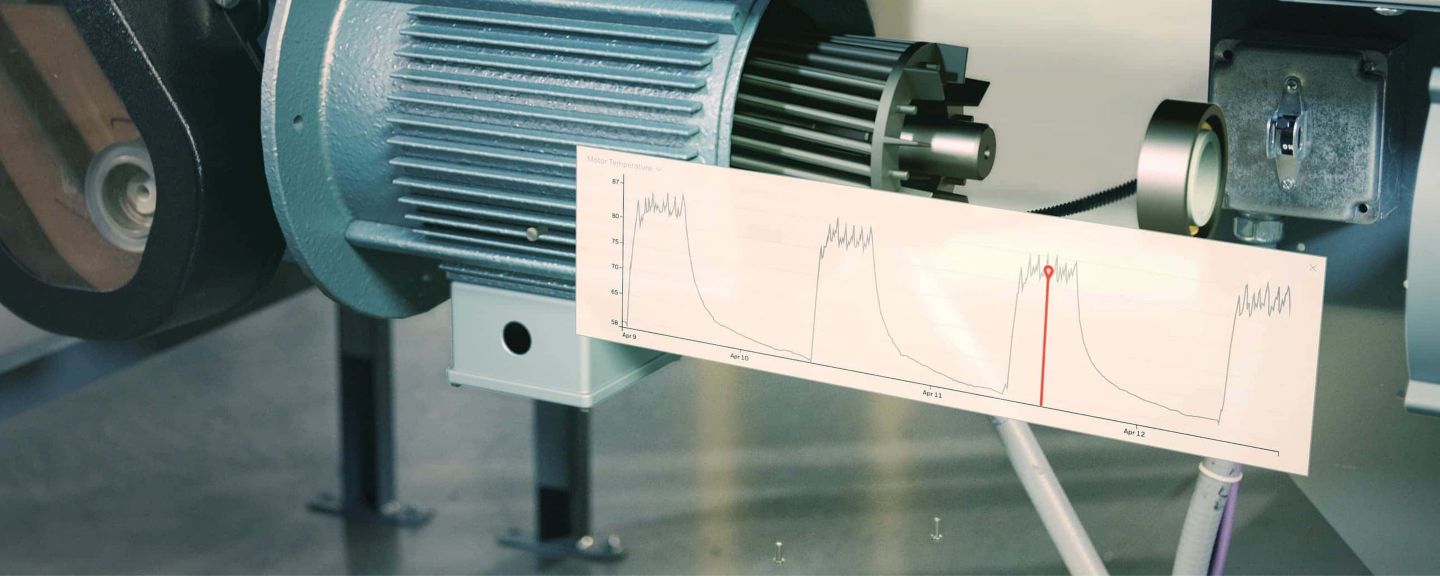

Effective outbound sortation systems are critical to ensuring maximum labor utilization and meeting customer service level agreements in distribution and fulfillment operations. Connected Assets by Honeywell Intelligrated builds upon our Connected Distribution Center infrastructure to help DC operators keep critical sortation systems running at peak productivity levels.

Connected Assets continuously accumulates data on equipment and system health to give you real-time statuses and historical insights into your sortation system’s overall performance. The system detects equipment degradation and process inefficiencies to help you identify fault conditions that could limit productivity or threaten uptime. With Connected Assets, you can:

- Receive real-time notifications of issues affecting an asset or process

- Uncover hidden areas of utilization

- View current system status and historical data trends for accurate forecasting

- Preempt and predict unplanned downtime

How it works: connected architecture

Connected Assets starts by connecting sortation machine control systems to extract operational data. This gives you access to performance dashboards to monitor sortation system and sub-system statuses, including:

- Merge rates, lane flow balancing

- Scanner read rates, recirculation rates

- Downtime, throughput

- Asset utilization

- Trending graphs for intuitive system visualization

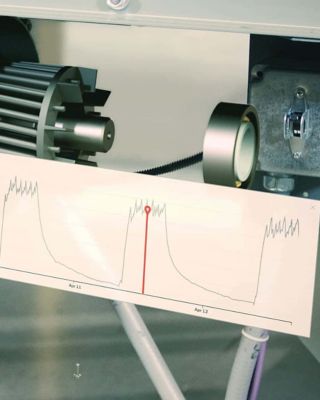

Add machine-level sensors on key points of your sortation system to monitor equipment health and trending performance insights, such as:

- Motor gearboxes — temperature and vibration

- Power control panel — voltage, amperage and electricity consumed per case shipped

- Facility temperature and humidity — facility baselines and weight-scale adjustment considerations

Connected control systems and machine-level sensors combine to provide insights into your sortation system’s real-time and historic trends.

Connected Assets utilizes a proven software suite that’s been used for decades in critical process industries.

- Pulse™ mobile app — receive alerts and triage issues

- Uniformance® Asset Sentinel — view live performance and asset health dashboards

- Uniformance Insight — access historic trends on asset condition and system performance

Combined, these tools allow DC operators and enterprise managers to make informed decisions, take decisive actions, and accelerate issue resolution.

Detect. Preempt. Predict.

As the platform accumulates data on each of these systems, sub-systems and KPIs, it’s able to develop trending information on performance and asset health. Enterprise managers and DC operators can leverage these historic and real-time insights to preempt and predict equipment failures, and drive process efficiencies:

- Sortation scanner misreads and “bad gaps” that overload recirculation conveyors

- Excessive conveyor motor vibration, indicating imminent failure

- Inefficient, manual activation/deactivation of merge lanes

Related Content

연결합시다!

Honeywell에 회원가입해서 제품 업데이트, 기술 정보, 신제품, 행사 및 소식, 설문 조사, 특별 할인 관련 내용을 전화, 이메일, 기타 방법을 온라인을 통해 받아보세요.

Copyright © 2026 Honeywell International Inc

Maximum File Size

Maximum Files Exceeded

해당 국가에서는 이 제품을 사용할 수 없으므로 이 페이지에 액세스할 수 없습니다.