Did you know that the first retail item to be scanned at checkout using a Universal Product Code (UPC) was a pack of chewing gum? Since this first scan in Troy, OH of the now ubiquitous UPC in 19741, the last 45 years have seen the proliferation of barcode readers, which are now prominent in almost every industry.

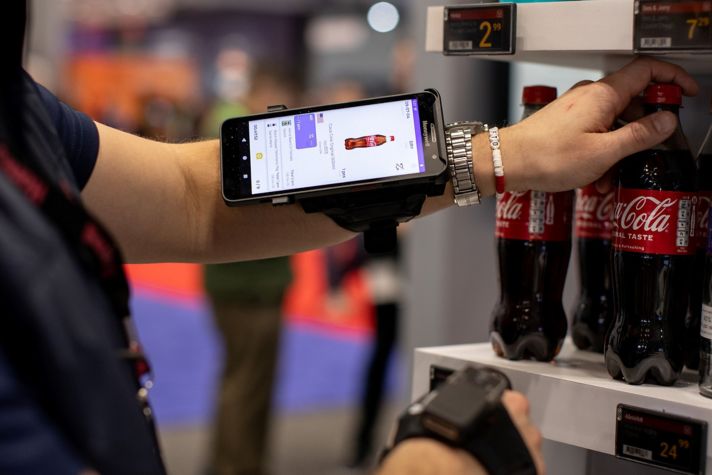

Scanning solutions will continue to transform the way we live and work, supporting contactless technology, self- service applications and automation. In fact, VDC Research predicts the original equipment manufacturer (OEM) scan engines market will grow to $395 million by 20252. With a wide range of OEM barcode solutions available and a deep understanding of your application requirements and operating environment conditions, Honeywell has been a trusted partner to OEMs. We have developed this short guide to highlight important factors that may impact your scanning application performance.

Read Range

An extended reading range may be required for applications where workers have a need for near, mid, and far scanning. Being able to switch seamlessly between near and far can also improve workflow efficiency and reduce fatigue.

Dimensions

As scan engines evolve, the design is becoming more compact. An ultra slim form factor allows customers to build lighter, smaller, and ergonomic mobile devices, including drones, robots, and wearable devices. This is also an important design consideration for fixed applications. For example, kiosks are changing to support more interactive and self-service functionality, with larger screens and more compact embedded technologies.

Motion Tolerance

Motion tolerance can improve scan performance by handling movement and delivering faster reading. This is particularly important for continuous use applications, like sorting machines, where large volumes of barcodes are moving at high speeds. Global shutter technology increases snappiness to improve productivity with faster scanning.

Power

Lower power consumption can translate into longer battery life in a single charge – keeping workers connected longer. It can also enable faster “wake-up time” for unattended scanning, which is needed in many applications, like smart lockers, for example.

Temperature

If scan engines are embedded in a platform with a computer, display and electronics, the operating temperature can increase significantly. This is without consideration of external temperatures, for example, if outdoors, temperatures can fluctuate. It is important to select a scanning solution that can perform even in extreme temperatures.

Light

Scanning must be able to function quickly and accurately under all lighting conditions - from the glare of bright sunlight, which impacts applications like outdoor kiosks and smart lockers, to low light environments, typically found in warehouses and distribution centers. Bright LED aimers and laser aimers can help end-users point and scan across a range of lighting conditions. Another consideration is the type of illumination configuration that is suitable for your application and workflow. Using LED illumination in consumer-facing environments is encouraged to enable a safer customer experience.

Other Hazards

Many embedded applications may be exposed to water and dust, as well as vibration, drops and shocks from operating in more rugged environments, like the warehouse. You also need to be able to read low-quality barcodes, due to damage, distortion, poor contrast or challenging package shapes and materials.

Honeywell - A Partner You Can Trust

As a global leader with more than 45 years of scanning innovation, Honeywell serves customers in almost every industry. We have taken a lead role in designing, engineering and manufacturing vision solutions including optical scan engines, all-in-one modules and decoder boards. Our engines are designed to reduce integration time and design costs, while increasing design choice and flexibility. SwiftDecoder™ barcode software allows end-users to acquire and process data and images quickly and reliably in the most complex workflows and has capabilities beyond barcode reading, such as augmented reality (AR) and optical character recognition (OCR). By integrating Honeywell technology into your designs, you can improve operational productivity and performance, while delivering excellent user experiences and customer satisfaction.

1 Nelson, Benjamin (1997). Punched Cards to Bar Codes: A 200 Year Journey with Descriptions of over 260 Codes. Peterborough, N.H.: Helmers Publishing. ISBN 978-091126112-7.

2 2022 VDC Research, OEM Barcode Scan Engines

Other sources used: www.accenture.com/us-en/insights/cloud/edge-computing-index