From field to table, the transportation of food is no small feat. Extensive supply chains spanning the globe must adhere to strict timetables, requirements, and processes to ensure that food reaches businesses, grocers, restaurants, and consumers in good condition. Many factors play a role in food quality by the time it reaches its destination, and those related to climate control are key.

In the United States alone, an estimated 30-40% of all food is wasted, approximately $160 billion in one year.[1] A significant portion (39%) of food waste occurs before the food ever reaches the end consumer. These losses can occur during harvesting, processing, transportation, storage, and distribution. Each point along the supply chain introduces unique challenges that must be managed for food to avoid premature spoilage and remain ready for consumption. Additionally, businesses recognize greater losses when food is lost further along in the supply chain.[2]

Humidity and temperature sensors, when utilized throughout the food supply chain, from harvesting to point of sale, have proven instrumental in reducing spoilage, improving safety, and extending shelf life. By properly monitoring and controlling humidity and temperature during the transportation of goods, business can potentially recover $65 billion dollars per year.

Understanding the Impact of Humidity and Temperature on Food Spoilage

From the moment food is harvested, an internal countdown begins, and suppliers need to have the right processes and equipment in place to ensure transportation regulations are followed and the food arrives before its expiration date. While all produce follows similar ripening processes, conditions influencing the rate of ripening vary. For example, apples need to remain at 90-95% humidity levels while avocados and grapes need 85-90% humidity.

When humidity and temperature levels are below the optimal range, produce begins to lose water, resulting in shriveling, lower weights, and wilting,[3] as well as increased susceptibility to mold and mildew.

When proper humidity and temperature levels are maintained, the ripening process can be controlled more closely, increasing the odds of produce successfully reaching its end destination. Some produce, such as pears, potatoes, and apples, can remain fresh for months when kept in an ideal environment, but spoil within days or weeks, when the environment is not controlled precisely.

Application and Benefits of Humidity and Temperature Sensors in the Food Industry

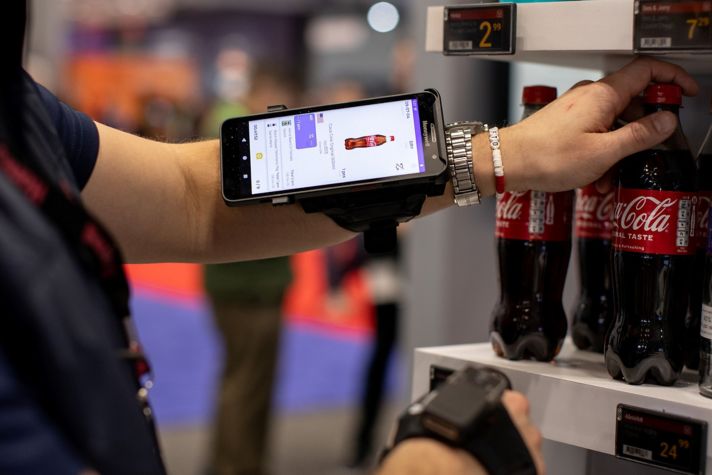

The sooner food can be placed in a controlled environment, under specific humidity and temperature (H/T) conditions, the more time it has to reach its destination. Therefore, the need for H/T sensors is crucial from the beginning and throughout the entire supply chain. As the IoT (internet of things) continues to grow, the importance of high-quality humidity and temperature sensors in the cold supply chain, and other industries, grows along with it.

In addition to recording H/T levels, live tracking allows businesses to recognize problems and resolve them before spoilage occurs and the food is lost. The constant monitoring and recording of H/T levels requires businesses to have a sensor that is durable and reliable.

Honeywell’s Humidicon series is a digital sensor that combines relative humidity and temperature sensing into one, reducing the need for multiple sensors, therefore reducing the number of failure points in the process.

Partnering with Honeywell

As supply chains continue to grow and connect businesses throughout the world, the need for accurate and reliable monitoring will continue to grow as well. Humidity and temperature sensors have a place in every aspect of the cold supply chain, and companies need durable sensors that provide consistent, accurate data at every turn. Honeywell’s digital Humidicon sensor provides long-term reliability and low drift, with a wide range of configurations to meet a diverse range of business needs.

Explore other Humidity and Temp Sensor applications. Honeywell has distribution channels throughout the US. Find a distributor & product availability here.

References:

[1] https://www.usda.gov/foodwaste/faqs