Sortation Systems

In today's on-demand economy, the speed and accuracy of your operation define your brand. Customers expect their orders to be correct and delivered faster than ever before. This puts immense pressure on your distribution center to sort and ship thousands of diverse items with near-perfect precision, especially during peak seasons. Manual or outdated sorting methods simply cannot keep up, leading to errors, delays, and dissatisfied customers.

Automated sortation systems are the engine of modern, high-volume fulfillment. By replacing manual, error-prone processes with high-speed, intelligent technology, you can dramatically increase your throughput, improve order accuracy, and meet the tight shipping windows your customers demand. These systems are the critical link that transforms a collection of picked items into perfectly consolidated and routed customer orders.

Common Challenges We Solve

Your sortation process is the heartbeat of your outbound operations. Our systems are specifically engineered to help solve the complex challenges that can slow you down.

![]()

High Rate of Mis-Sorts and Order Errors

Eliminate costly shipping errors and returns by replacing manual guesswork with automated precision. Our systems help get the right item to the right destination, consistently.

![]()

Inability to Meet Peak Season Demand

Stop letting seasonal spikes create backlogs and shipping delays. Our high-speed solutions are designed to handle massive volume surges, allowing you to meet your service-level agreements (SLAs) year-round.

![]()

Bottlenecks from Manual Sorting and Consolidation

Reduce the labor-intensive process of manually sorting items for different orders or shipping destinations. Automation creates a continuous, high-speed flow that breaks through operational bottlenecks.

![]()

Difficulty Handling a Diverse Product Mix

Your inventory is always changing. We provide a range of sorter technologies designed to gently and effectively handle everything from small polybags and jiffy bags to standard cases and totes.

![]()

Lack of Real-Time Visibility and Control

Gain insight into your outbound process with intelligent software that tracks every item. This data allows you to monitor performance, make adjustments, and confirm successful order processing.

Outcomes We Drive: Honeywell Sortation Systems

• Outcome: Rapid, accurate sorting of parcels, totes, and cartons to multiple destinations, enabling higher order fulfillment rates.

• Metric: Up to 99%+ sortation accuracy; sort thousands of items per hour.

• Outcome: Intelligent software integration ensures every item is routed to the correct lane, reducing costly mis-sorts and returns.

• Metric: Achieve less than 0.1% mis-sort rate; reduce added cost of mis-sorts and meet customer SLAs.

• Outcome: Modular sorters adapt to changing product mixes and volumes, supporting business growth and seasonal peaks.

• Metric: Scale your sortation capacity by 20–50%, with minimal downtime; handle diverse SKUs from polybags to heavy cartons.

• Outcome: Automated sortation reduces manual handling, labor costs, and energy consumption, while improving system uptime.

• Metric: Increase ROI by optimizing labor in the warehouse; reduce energy use by up to 30% with efficient sortation technology.

Key Industries & Applications

High-speed sortation is a mission-critical function for any industry focused on direct-to-consumer or business-to-business order fulfillment.

Parcel & Post

The core technology for hubs of all sizes, enabling the rapid sortation of millions of parcels per day for routing to various downstream delivery networks.

E-commerce Fulfillment

Essential for sorting picked items from batch-picking processes into individual customer orders, as well as routing packed orders to the correct shipping lane (e.g., ground, next-day air).

Retail Distribution

Used to sort cases and totes of merchandise for store replenishment, ensuring each retail location receives the precise inventory it needs.

Pharmaceuticals & Healthcare

Provides gentle, accurate handling and tracking for sorting sensitive and high-value orders for distribution to pharmacies, hospitals, or direct to consumers.

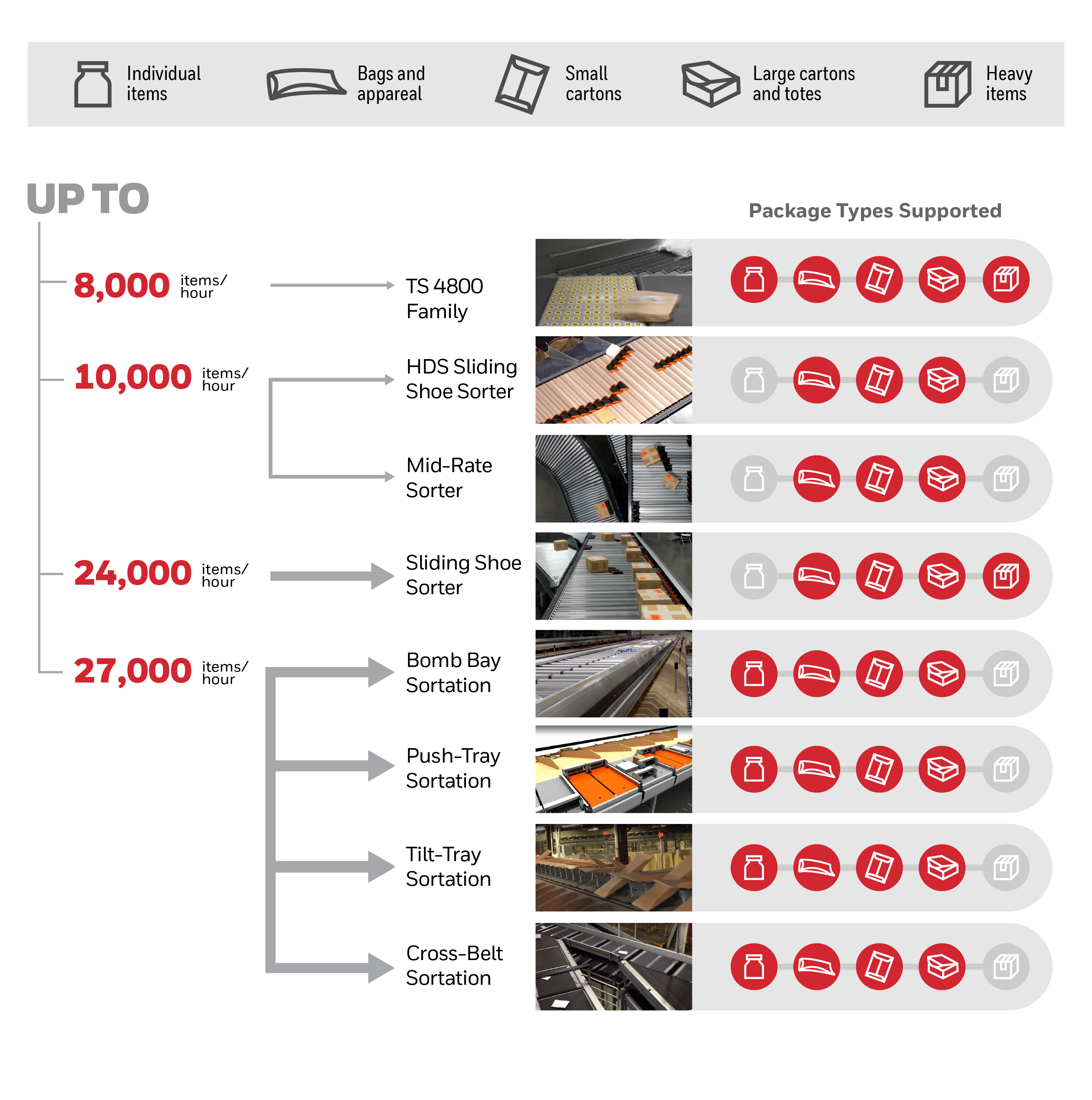

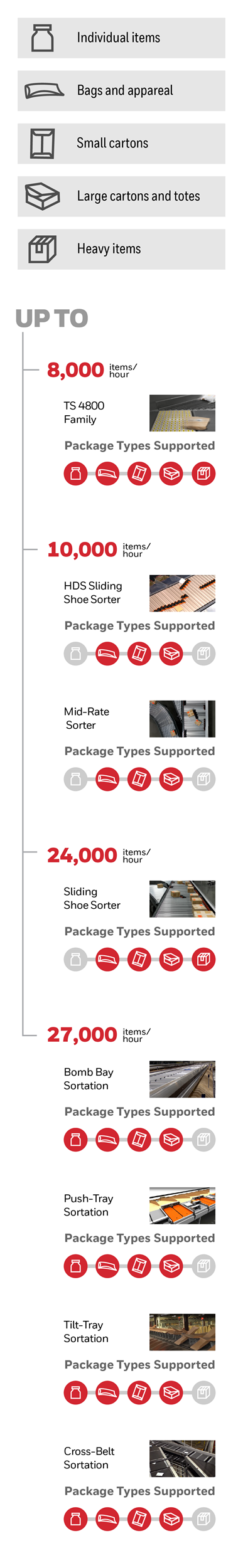

Types of Automated Sortation Systems

Choosing the right sorter depends on your required throughput, product characteristics, and facility footprint. We design customized solutions for your unique application.

SmartSort® Swivel Wheel Sorter

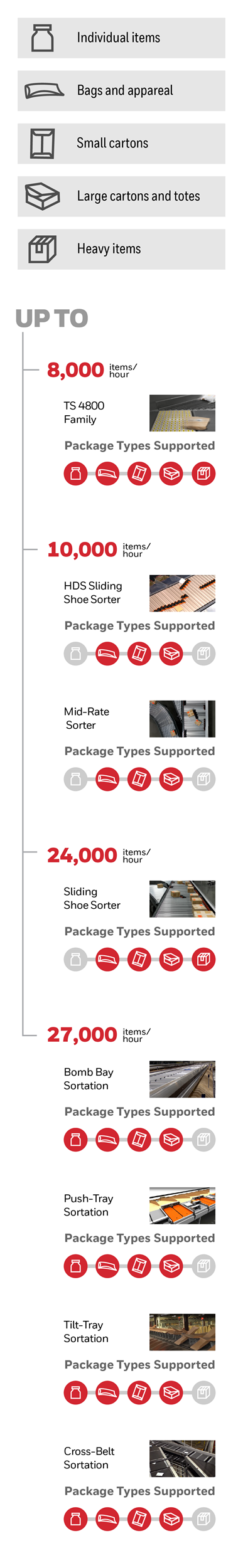

The Transnorm SmartSort® Swivel Wheel Sorter product family offers advanced solutions for high-speed sorting and distribution. This versatile range includes the Divert Conveyor TS4800, the Compact Sorter TS4800C, and the innovative Sorter Cartridge TS4810 — engineered to deliver distribution capacities ≥ 8,000 units per hour.

Designed and manufactured by Transnorm, the SmartSort® family is a modular, high-performance sorting solution tailored for the efficient sorting, outfeeding and distribution of unit loads. Its intelligent design incorporates electrically driven swivel bars, a central drive mechanism, and robust PU-coated rollers, ensuring gentle yet reliable handling of a wide variety of items over 100 millimeters in length. From shipping bags and small parcels to plastic containers, trays with waffle bases, and even tires, the system accommodates complex goods and manages them securely at high speeds.

Sliding Shoe Sorter

Up to 24,000 items/hour

Pioneered by Honeywell in the 1980s, the innovative sliding shoe sorter combines one of the highest throughput rates in the industry with the most accurate product handling.

Diverting “shoes” attached to the conveyor surface positively divert items onto an after-sort conveyor. A patented “soft touch” divert system provides fast, gentle control and accuracy, reducing item impact speed by 500%. Ongoing refinements have made the latest generation of shoe sorters quieter than ever, while offering the flexibility of modular design.

Fast, accurate handling of diverse items

Fed by a single stream of products merged from multiple areas of a building upstream, sliding shoe sorters are a popular choice for shipping sorters, as they can provide high rates with predictable divert accuracy for a wide range of items. They’re also a great choice for operations that handle polybags, jiffy bags and bubble mailers, because their innovative design eliminates potential pinch points.

HDS Sliding Shoe Sorter

Up to 11,000 items/hour

For applications that need to fit in limited spaces, the high density sliding shoe sorter (HDS) features a dual-sided design that accommodates more divert chutes in a smaller footprint. This configuration enables fast, precise diverts of a wide variety of product and packaging types — including polybags — while supporting zone-skipping strategies.

Mid Rate Sliding Shoe Sorter

The Mid-Rate Sorter is a strategic addition to Honeywell’s sortation portfolio, designed to support operations in need of 6,000-8,000 items an hour.

Incorporates high-density divert spacing and simplified mechanical/electrical systems to optimize footprint and cost, while maintaining the ability to handle diverse package types.

Bomb Bay Sorter

Up to 24,000 items/hour

Ideal for high-throughput, e-commerce operations, quiet, high-capacity bomb bay sorters run in a continuous loop, dropping items into cartons, totes or engineered packaging chutes. The flat carrying surface reliably handles polybags, round items that roll, non-conveyables, multimedia, mail and more. Bomb bay sortation solutions are available with single, dual or heavy-duty, split-tray styles.

Push-Tray Sorter

Up to 24,000 items/hour

Honeywell’s award-winning push-tray sorter is one of the most flexible mid-capacity solutions in the industry. Items are inducted onto carts running around a continuous loop, before being pushed off by a sliding bar. Push-tray technology combines the benefits of sliding shoe and tilt-tray sorters. A twin-tray design enables the handling of nearly all packaging types and sizes, from 200 g polybags to 20 kg cartons. In many cases, this versatile solution can even handle products that traditionally required manual sorting.

Tilt-Tray Sorter

Up to 27,000 items/hour

Tilt-tray sorters are engineered for critical high-capacity, high-speed sorting applications. Trays mounted to carts running on a continuous-loop conveyor “tilt” and transfer items down into a chute when an item reaches its sorting destination. Items are inducted either manually or automatically onto the trays via induction station sat multiple locations throughout the loop.

Durable, low-maintenance tilt-trays accommodate nearly all item sizes, deliver high throughput and accuracy, and are ideal for applications that require a high number of sort locations. Low noise levels make atilt-tray sorter a good solution for operators who work in close proximity to a machine. In addition, virtual sorter capability enables dual-purpose operation for peak capacity and high-volume runs.

Flexible performance in tight spaces

The low-profile frame of the tilt-tray sorter allows for clearance in otherwise tight locations. Its modular design enables the system to scale easily, accommodating future expansion or seamless integration into existing facilities.

Cross-Belt Sorter

Up to 27,000 items/hour

Honeywell’s high-capacity, flexible cross-belt sorter is designed to handle fragile and high-friction items of virtually any size. Motorized belt conveyors are mounted onto carts running on a continuous loop conveyor and transfer items down into a chute when an item reaches its sorting destination. Two belt units per cart — which give the cross-belt sorter its name — can handle large items while increasing capacity for small-to-medium-size items.

The system’s flexible modular design easily scales and adapts to your operation’s current and future needs.

Tilt-tray or cross-belt?

While cross-belt technology offers similar functionality and features as tilt-tray sorters, they provide more predictable divert reliability for certain types of products and packaging. They provide unmatched throughput for high-friction pieces or those that need gentle handling, including tricky items like letters, flats, books, CDs and DVDs.

Precision Control for Peak Performance

Frequently Asked Questions

Throughput rates vary significantly based on the type of sorter and average product size. For example, one Honeywell Transnorm TS 4810 compact sorter can deliver dynamic distribution of over 8,000 units per hour. We will model your specific operational data to recommend a system that meets your peak requirements.

This is a critical consideration in our design process. For operations with a high volume of fragile goods or flimsy polybags, a cross-belt sorter is often the ideal choice due to its gentle, carrier-based handling. For more robust items, a sliding shoe sorter provides a great balance of speed and gentle product control.

Our Momentum WES is designed to be the integration layer between your WMS and the material handling equipment. Your WMS will continue to manage inventory and orders, passing the sortation requirements to Momentum. Momentum then translates those requirements into real-time commands for the hardware, ensuring seamless communication and operation.

The footprint depends on the sorter type, length, and the number of required divert destinations. Loop sorters, like cross-belts, can be designed in various configurations, including stacked or multi-level layouts, to make the most of your available vertical space and minimize the impact on your facility floor.

Turn Throughput Challenges into a Competitive Advantage

Ready to increase your fulfillment speed and achieve new levels of order accuracy?

Our team is ready to analyze your unique product mix and volume requirements to design the optimal automated sortation solution for your business.