-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

-

Currency:Localize your Content

You can set your preferred currency for this account.

Choose a Currency

Currency- CHOOSE YOUR CURRENCY

Update Currency

Changing Currency will cause your current cart to be deleted. Click OK to proceed.

To Keep your current cart, click CLOSE and then save your cart before changing currency.

-

Select Account

Switching accounts will update the product catalog available to you. When switching accounts, your current cart will not move to the new account you select. Your current cart will be available if you log back into this account again.

Account# Account Name City Zip/Post Code CANCELPROCEEDMy Account

-

Global

-

Africa

-

Asia Pacific

-

Europe

-

Latin America

-

Middle East

-

North America

- |

- Partners

- |

You are browsing the product catalog for

You are viewing the overview and resources for

- Products

- Warehouse Automation

- Solutions by Technology

- Conveyor Systems

- Merging & Diverting Conveyor

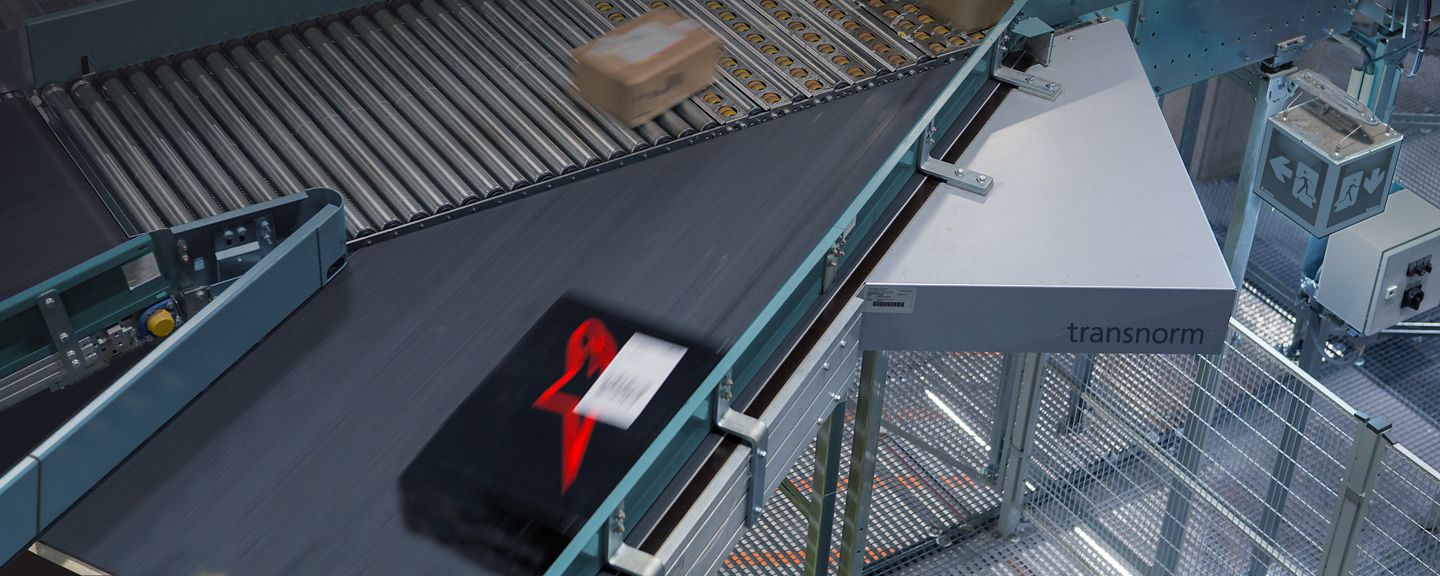

Merging & Diverting Conveyors

Reliably Connect Multiple Conveyor Systems With Integrated Mergers and Diverts

Complimentary connection between adjacent conveyors is imperative when merging and diverting. Reliably connecting multiple lines, either horizontally or vertically enables consistent onward flow and accurate handling of loads – whether that be the feeding of a sorter in a Parcel hub or a Baggage Handling System.

Offering a wide range of functional junction conveyors, we solve industry specific requirements common in a wide range of applications.

Full Belt Merge – TS 6200 / TS 4200 (US Market)

Transnorm Junction Conveyor with full belt design - Reliable and accurate

The Transnorm Junction Conveyor is a belt conveyor with an angled terminal at one end allowing product to feed onto or discharge from a main line at 30° or 45°. Using a single width belt and small diameter fixed-position terminal pulleys, it is possible to handle a wide variety of products with only a small gap to the adjacent conveyor. Available in either a merging or diverting version, the drive station is configured to suit the conveying direction and can easily be changed in a few simple steps.

The Transnorm Junction Belt Conveyors offer the following advantages:

- Optimal transfer of force for reliable operation with exemplary smoothness during operation

- Specially coated pulleys for extremely low values of friction

- Belts can be changed from above

- Small gap to adjacent conveyor

- Possible to handle a wide variety of products

Strip Merge – TS 6240 / TS 6260

Transnorm Strip Belt Conveyors

Transnorm Strip Belt Conveyors are robust and economical belt conveyors for inward and outward transfer applications with an angle of 30 or 45 degrees. Their design permits the efficient merging or diverting of unit loads at high speed - even for reverse operations. The nominal angle of the conveyors is implemented by using different lengths in the strips forming the belt. The smooth and continuous arrangement of the belts and consequent prevention of pull-in points ensures fault-free operations.

The Transnorm Strip Belt Conveyors offer the following advantages:

- Reliable operation with exemplary smooth running

- High conveyor speeds even for reverse operation

- Compact and robust design and construction

- Low-friction operation reduces the power consumption and the wear is kept to a minimum

Powered Belt Diverter – TS 6510

Transnorm Powered Belt Diverter Airport Solution - A compact stand-alone solution

The motorized belt diverter from Transnorm has been specially customized to meet the merging and diverting tasks of baggage handling systems at airports. With a diverting capacity of up to 1,500 units per hour, it is used wherever pieces of baggage need to be discharged from a conveyor line or have to be diverted to a conveyor line. With this compact stand-alone solution, it is necessary to have a positive fit connection to the adjacent conveyor equipment. As a result, the often problematic clarification of interfaces during the integration phase is removed.

The Transnorm Powered Belt Diverter offers the following benefits:

- Simple and robust construction for standard flight baggage

- No positive fit connection to the adjacent conveyor equipment is required

- Simple integration and no cumbersome explanation of the interfaces is necessary

- Driving and deflection drums located inside enable a very small gap between the conveyor belt and discharge belt

- Low noise operation while running

- Extremely low maintenance with high idle times

Transnorm Roller Merge – TS 2964

Transnorm Roller Merge – Contactless merging with high performance and speed

When it comes to merging two input lines with high throughput without the loads making contact, the Transnorm Roller Merge is ideal. Delivering contactless merging, the loads to be transported run through the Roller Merge without contacting with guide elements to the side. This solution therefore prevents flat goods, such as envelopes or film packages from becoming jammed below the lateral guides.

The Transnorm Roller Merge offers the following benefits:

- Contactless merging of even flat goods such as envelopes or film packages

- Large range of products based on the low roller diversion of 55mm

- Timing operation is possible to some extent in the design using rubberized rollers

VertiSwitch® – TS 6610

Compact and powerful – Vertical Line Diverters for Intralogistics

The Transnorm VertiSwitch® is a completely standardized, vertical distribution unit which can be deployed optionally as a diverting unit (line distribution) or merging unit (line consolidation). Characterized by an open and robust construction, modular design and a high level of dynamism in the swivel movements.

The Transnorm VertiSwitch® offers the following benefits:

- Innovative design with minimum energy consumption

- Light yet rugged design with high reliability

- Compact design for minimal space requirements

- High speed operation combined with low noise operation

- Low maintenance requirement

- Usable as a line diverter or merge

Merging & Diverting Conveyor

Let's Connect!

Sign up to receive exclusive communications from Honeywell including product updates, technical information, new offerings, events and news, surveys, special offers, and related topics via telephone, email, and other forms of electronic communication.

Copyright © 2025 Honeywell International Inc

Maximum File Size

Maximum Files Exceeded

Due to inactivity you will be logged out in 000 seconds.

Maximum File Size

Maximum Files Exceeded

You cannot access this page as this product is not available in your country.