-

Currency:Localize your Content

You can set your preferred currency for this account.

Choose a Currency

Currency- CHOOSE YOUR CURRENCY

Update Currency

Changing Currency will cause your current cart to be deleted. Click OK to proceed.

To Keep your current cart, click CLOSE and then save your cart before changing currency.

-

Select Account

Switching accounts will update the product catalog available to you. When switching accounts, your current cart will not move to the new account you select. Your current cart will be available if you log back into this account again.

Account# Account Name City Zip/Post Code CANCELPROCEEDMy Account

-

Products

- View All Control & Supervisory Systems

- Control Systems Parts & Accessories

- Distributed Control Systems (DCS)

- Safety Systems

- SCADA

- Quality Control Systems (QCS)

- Modular Controllers

- Human Machine Interfaces (HMI)

- Remote Terminal Units (RTU)

- Drives

- Modular Systems Remote IO

- Discrete Automation Solutions

- View All Regulators & Safety Accessories

- High Pressure Regulators up to ANSI 600

- High Pressure Regulators up to PN40 (ANSI 300)

- Medium Pressure Regulators PN16 (ANSI 150)

- Pilot Heater

- Safety Relief Valves

- Safety Shut-Off Valves

- Small Pressure Regulators (Pressure Reducer)

- Control Equipment for Safety Shut-Off Valves

- Pilot for Gas Pressure Regulators

- Gas Filters, Valves & Components

- Regulators & Safety Accessories Spare Parts

- View All Fixed Gauging

- PL3700X Pressure and Level Transmitters

- EM540 & EM940 Radar Level Gauge

- T901 Temperature and Pressure Transmitters

- Lidec Liquid Level Switch

- CT801 Electropneumatic Level Transmitters

- Communication Interface Unit

- CargoBoss Tank Gauging Software

- Spare Parts & Accessories - Marine Fixed Gauging

- Water Ingress Detection System

- CARLA Overfill Detection System

- GASBAL™ Gas Detection System

- Q96 Analog Indicator

- View All Portable Sampling

- HERMetic Sampler GT & Sampler GT Chem for Marine Applications

- HERMetic Sampler GT1 for Marine Applications

- HERMetic Sampler GTX for Marine Applications

- HERMetic Sampler GTN for Marine Applications

- HERMetic Sampler GT4 for Marine Applications

- HERMetic Samplers for Restricted Operations

- Spare Parts - Marine Portable Gauging & Sampling

- Ballast Water Sampler

- Gauging and Sampling for high-pressure Tankers

- View All Marine Pressure Transmitters

- SmartLine STF800 - Flange Mount

- Remote Diaphragm Transmitters - SmartLine STR700

- SmartLine STR800 - Remote Diaphragm

- SmartLine STD800 - Differential Pressure

- Differential Pressure Transmitter - SmartLine STD700

- Gauge Pressure Transmitters - SmartLine STG700

- SmartLine STG800 - Gauge Pressure

- Flange Mount Transmitters - SmartLine STF700

- Absolute Pressure Transmitter - SmartLine STA700

- SmartLine STA800 - Absolute Pressure

- View All Portable Gauging & Sampling for Terminals

- HERMetic Sampler A-2 and A-4 - Land Applications

- HERMetic Sampler GT & Sampler GT Chem - Land Applications

- HERMetic Sampler GT4 - Land Applications

- HERMetic Sampler GTN Chem - Land Applications

- HERMetic Sampler GTX Chem - Land Applications

- HERMetic UTImeter Otex - Restricted Type - Land Applications

- HERMetic UTImeter Gtex 2000 - Closed Type - Land Applications

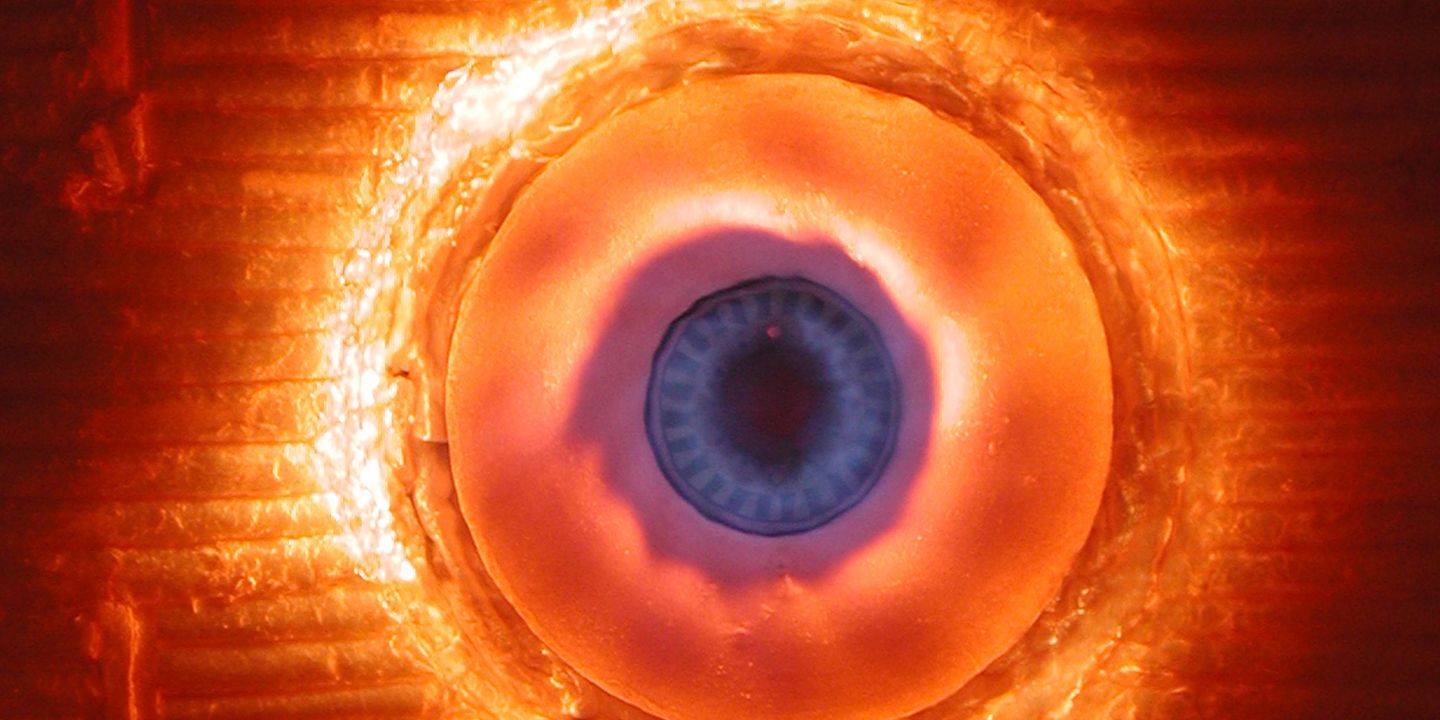

- View All Burners & Heat Exchangers

- Direct Fired Furnace Burners

- Self-Recuperative and Radiant Tube Burners

- Single Burners

- Line & Duct Burners

- Glass & Oxygen Burners

- Immersion Tube Burners

- Hauck Asphalt Burners

- Exothermic Heat Exchangers & Indirect Heaters

- Pre-Mix Equipment

- Pilot Burners

- Burner Accessories

-

Services

Services

-

Cybersecurity Services

Highly skilled OT cybersecurity consultants can provide services to support your cybersecurity needs.

-

Fire & Gas Services

Process fire and gas systems play a key role in protecting valuable production assets.

-

Control System Services

Modernize systems, optimize performance, and help mitigate cybersecurity risks.

-

Combustion Services

Technical services and engineered solutions for fuel-fired equipment across all major industries.

-

Training

Honeywell Academy offers a variety of courses to keep your workers updated on the latest technology.

-

Utility Services

Industry services, including: AMI upgrades, gas line locating, and water leak detection.

-

Smart Grid Solutions & Services (SGS)

Comprehensive energy efficiency solutions for the Utility Industry

-

Maintenance Assist

Maintenance Assist is Honeywell’s advanced Generative AI digital assistant designed to streamline maintenance tasks and enhance efficiency.

-

Cybersecurity Services

-

Support

Support

-

Technical Publications

Sign in to search, preview and download technical documentation.

-

Channel Partner Program

Access to Honeywell Process Solutions' Channel Partner Program.

-

Find a Channel Partner

Locate an authorized Honeywell Process Solution Partner for your Sales and Service needs.

-

Knowledge Articles

Search our Knowledge Base for support material, notifications, solutions and knowledge sharing.

-

Customer Service Request

Contact Customer Care to edit & cancel orders, find stock availability, expedite requests and more.

- PMC Training

-

Technical Publications

You are browsing the product catalog for

You are viewing the overview and resources for

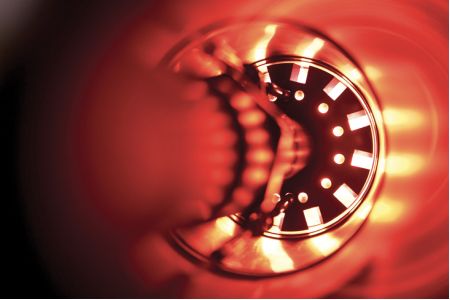

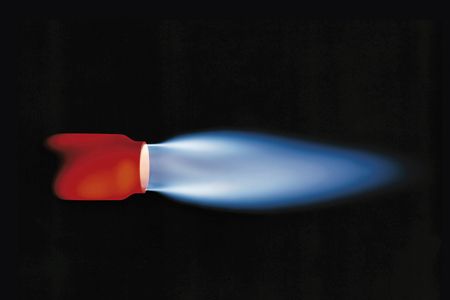

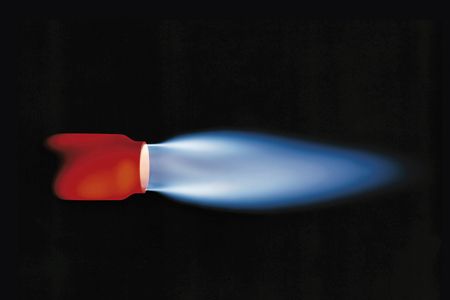

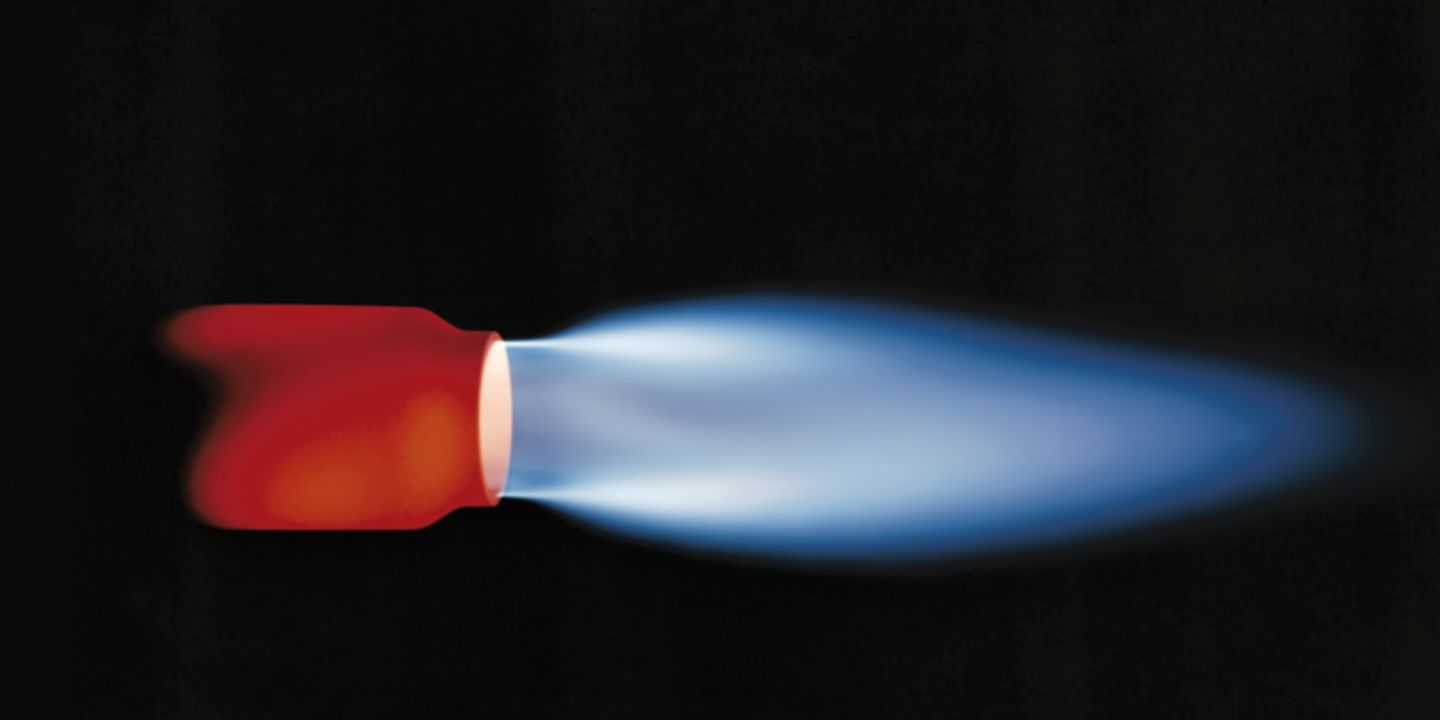

Forging Thermal Innovation Fueling Thermal Progress

Our wide range of thermal solutions helps OEMs and end users improve the thermal efficiency and sustainability of equipment and processes in the metals industry.

Meet Global Emissions Requirements With ECOMAX® LE Burner

This asset includes practical guidance for OEMs and end-users as they select the right burners and controls for specific industrial heating applications.

Combustion Control by Pulse Firing

Gain greater control of heat input with pulse firing, a combustion technique that provides increased flexibility, temperature uniformity, efficiency, and emissions reduction.

Ferrous and Non-Ferrous Metals Processing

For over 125 years, Honeywell Thermal Solutions’ thermal portfolio of burners, controls and heat recovery systems has been an integral part of customers

who sell to or are end-users within the secondary upstream and downstream metals markets.

Regardless of the metals vertical, Honeywell Thermal Solutions systems are integral to successful metal treatment. If you are an OEM,

system integrator or end-user, we have the experience, expertise and widest portfolio of solutions to help solve your application challenges.

Integration-Ready Equipment. Iron-Clad Expertise.

End-users require safe, high-performance equipment. That’s why we design and engineer trusted burners, controls and heat exchangers to easily integrate with OEMs’ furnaces, ovens and other equipment. Honeywell Thermal Solutions also has a global, engineered-to-order team that can develop customized combustion solutions for end-users and OEMs who want to add sustainability, reliability and efficiency to their processes and equipment.

Thermal Performance Matters to All

Whether you supply the equipment that’s used during heat treatment or use equipment to thermally treat metals as part of your daily operations, we help make sure it operates at the highest level.

Our proven, trusted thermal solutions effectively dissipate heat, capture and reuse energy, control temperatures and withstand high heat in furnaces, ovens and other thermal equipment. This helps reduce energy consumption, reduce emissions and improve combustion efficiency to keep product quality and equipment functionality high.

Different applications require different solutions, including those that achieve greater thermal transfer, better fuel delivery and complete burner management. All help add flexibility and performance to equipment, operations and processes.

Thermal Solutions, Efficiency and Sustainability in Action

When we say our solutions help give OEMs and end-users greater control and significant results, we mean it. From performance upgrades to sustainability enhancements, our burners, heat exchangers and controls help processes in the metal industry become more advanced, reduce emissions and improve energy conservation.

See more resources here

Copyright © 2025 Honeywell International Inc.

Maximum File Size

Maximum Files Exceeded

Due to inactivity you will be logged out in 000 seconds.

Maximum File Size

Maximum Files Exceeded

Honeywell International Inc. is committed to ensuring compliance with global laws that regulate its export and import activities. In following company procedures, it has been determined that is identified on a denied/restricted parties list that is applicable to this transaction.

As a result, Honeywell is unable to continue with this request.